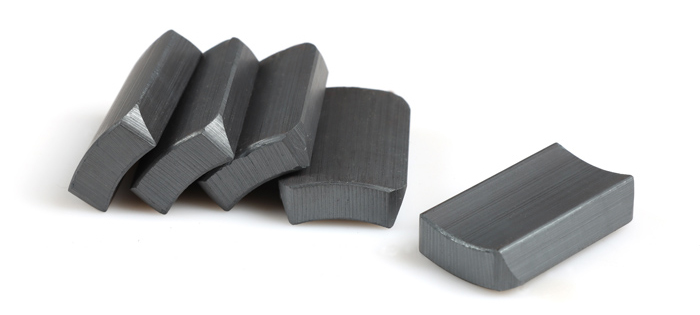

Ferrite Arc Permanent Magnet For Motor

The company magnetic tile is applied in drum washing machine, wave wheel washing machine, clothes dryer, dishwasher, small and medium-sized industrial motor, automobile motor, office equipment motor, environmental protection, energy saving, highly efficient refrigerator compressor and other fields.

- MGC

- Ma'anshan City, Anhui Province

- According to customer order quantity

- 10,000 tons/year

- Information

The company magnetic tile is applied in drum washing machine, wave wheel washing machine, clothes dryer, dishwasher, small and medium-sized industrial motor, automobile motor, office equipment motor, environmental protection, energy saving, highly efficient refrigerator compressor and other fields.

apple

Sintered ferrites (also known as ceramic magnets) were developed and produced in the 1950's;

Sintered ferrite magnets mainly include barium ferrite (BaO•6Fe2O3) and strontium ferrite (SrO•6Fe2O3); sintered ferrite is divided into isotropic magnets and anisotropic magnets.

Performance: The magnetic properties of isotropic sintered ferrite are weak, and have the same magnetic properties in any direction.

Multi-pole magnetization in any direction; Anisotropic sintered ferrite magnets have higher magnetic properties than isotropic ones,

It can only be magnetized in the orientation direction of the magnetic field during molding; the main raw material of sintered ferrite is oxide,

Therefore, it will not be corroded by high temperature, high humidity or chemical substances (except strong acid and alkali).

Application field: Because the raw materials are cheap and the production process is relatively simple, the cost is low,

Therefore, sintered ferrite is by far the most widely used permanent magnet material;

It is widely used in permanent magnet motors, DC motors, speakers, reed switches, magnetic separators and adsorption devices, etc.

Others: sintered ferrite has excellent demagnetization resistance, no magnetic flux loss before and after assembly and magnetization;

The working temperature of sintered ferrite is -40°C to +250°C, and the temperature coefficient is poor;

The temperature coefficient of Br is -0.2%/°C, that is, for every 1°C increase in temperature, Br decreases by 0.2%;

Sintered ferrite has high hardness and can be processed by wire cutting and grinding;

Sintered ferrite is brittle and fragile, so it should be handled with care during production and transportation.