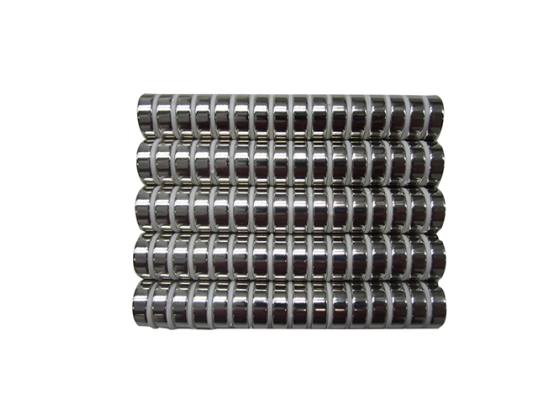

Small Thin Round Flat Strong Magnets

Ma'anshan High-Tech Magnetic Materials Co., Ltd. was founded in September 1993. It is an advanced technology enterprise with high-performance permanent magnet ferroxy material production, operation and science and technology development, and belongs to the electronic information materials industry.

- MGC

- Ma'anshan City, Anhui Province

- According to customer order quantity

- 10,000 tons/year

- Information

Ma'anshan High-Tech Magnetic Materials Co., Ltd. was founded in September 1993. It is an advanced technology enterprise with high-performance permanent magnet ferroxy material production, operation and science and technology development, and belongs to the electronic information materials industry.There are 180 employees, and engineering and technical personnel accounting for more than 20% of the total employees.Annual production capacity of the leading product: 6,000 tons of high-grade permanent magnet oxide.The quality level of leading products is in the leading level of domestic peers.The products are widely used in automobile, household appliances, and other fields, with good market prospects and broad development prospects.The products not only sell well in China, but also are exported to the United States, Europe, Japan, Southeast Asia and other countries and regions.The company has won the honorary titles of "High-tech Enterprise", "Anhui Province Small and Micro Growth Enterprise", "Anhui Province Special and Special New Enterprise", "Ma 'anshan Science and Technology Little Giant" and so on, and has the import and export right of the People's Republic of China.

Manufacturing Process of Neodymium Magnets (NdFeB)

Neodymium rare earth magnet alloys are made from an alloy mainly composed of neodymium (Nd), iron (Fe) and boron (B), with the addition of additional elements, depending on the grade of magnets produced and the temperature required for operation Typically consisting of aluminum (AL), niobium (Nb), and dysprosium (Dy), after mixing, the elements are placed in a vacuum furnace where they are heated and alloyed through a vacuum induction melting process that uses an electric current to melt the elements while keeping them free of contamination thing.

melting and grinding

Once all the ingredients are obtained, they are usually melted with an electric current to form lumps or bars. These alloy ingots are then ground or pulverized into powder and mixed in preparation for pressing by means of a jet mill, which allows the creation of particles of a specific size. The composition and mixture of the alloy determines the strength, grade and other characteristics of the magnet, and for the production of neodymium magnets, the abrasive particle size is usually around 3 microns.

Press and magnetize

After the grinding process, the particles are pressed together. The method used varies depending on the magnet grade produced and the manufacturer. The three main pressing methods are axial, transverse and isostatic pressing. During pressing, an external magnetic field is applied to align and set the magnetic domains of the particles in one direction, called the magnetization direction. After the pressing process is complete, the material is demagnetized prior to sintering, which involves heating the material in an oxygen-free environment to extremely high temperatures but below the material's melting point. After pressing by applying a magnetic field to give the preferred direction of magnetization, magnet manufacturers end up with a block that is sintered to give it sharper magnetism.

sintering

After pressing, the magnets are not yet very strong, and sintering helps lock the magnetic particles in place by applying heat, carefully heating the alloy mixture to a temperature high enough to stick but low enough to avoid liquefaction. Sintering fuses the already compacted particles together to form a solid mass, and a complete magnet is rapidly cooled through a process called quenching, maximizing magnetic properties and minimizing the potential for alloy variant with poorer magnetic properties.

Machining

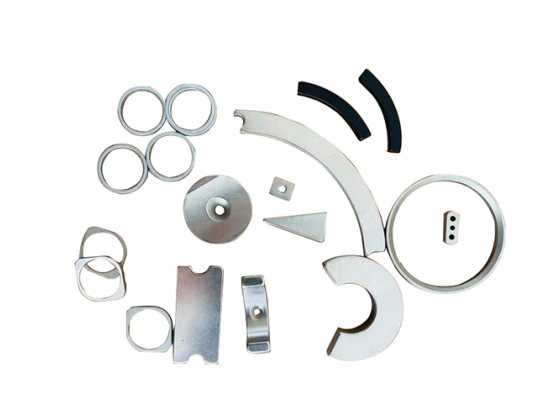

Sintering typically shrinks magnets, often requiring specific sizes and shapes for their respective applications, so a process called machining is used to define the shape and tolerances. After cooling, the magnets are machined into the desired shape using wire-cut electric discharge or diamond cutting tools, and cleaned and dried before electroplating to prevent corrosion.

Plating

Neodymium will corrode, so to prevent corrosion, there is a coating on the magnet. Most neodymium magnets are first plated with a layer of nickel, then plated with a layer of copper, and finally plated with a layer of nickel. It can also be used according to specific requirements. Other professional coatings and coatings.

magnetization

Now the magnets are almost ready, but they are not yet fully magnetic, in other words, they have been assigned a pole orientation, but the magnetic force has not been activated, and they will not exert their full magnetic power to attract or repel. To activate their magnetism, industrial magnetizers are often used. The magnet block is placed in it and exposed to a strong magnetic field, then the magnet is placed inside the solenoid coil and exposed to a magnetic field at least 3 times stronger than the required strength of the magnet and magnetized to saturation for maximum magnetic output, which This is achieved by aligning the magnet and its magnetization with the magnetic field.

Magnetic pole direction

Pole Orientation The easiest way to identify a magnet's poles is to use a numeric pole identifier, or to use a magnet with an identified pole. Identifying the pole orientation of a magnet A compass is sufficient, when using a compass to identify the poles of a magnet it is important to remember that the poles are attracted to their opposite poles, the compass needle itself is a small bar magnet so there is a North Pole and one South Pole.

The alignment of the magnetic poles can be observed by using a magnetic viewing film, which reacts to the magnetic field lines of the magnet below it. The dark areas of the viewing film represent the pole faces and the light areas represent the gaps between the poles. By measuring the gap between the magnetic field lines, the pole spacing (frequency) can be determined, and the magnetic viewing membrane does not indicate whether the north pole is north or south. Magnetic observation films contain a colloidal solution of tiny nickel flakes suspended in a viscous oily substance. Nickel is ferromagnetic and the flakes react under the action of a magnetic field. When suspended in solution and simultaneously exposed to a magnetic field, they can rotate unhindered, aligning them along magnetic flux lines.